Asbestos Board Removal

What is an asbestos insulation board (AIB)?

Asbestos insulation board (AIB) is a high-grade building material used extensively in UK properties until the late 20th century. It often contains up to 100% asbestos fibres, making it extremely dangerous when disturbed. Unlike asbestos cement, which is denser and less likely to release fibres, AIB is friable, meaning it can break apart easily and release microscopic, cancer-causing fibres into the air.

AIB was valued for its strength, fire resistance, and thermal insulation, but today, it’s considered a high-risk licensed material. Under UK law, its removal must be carried out only by HSE-licensed contractors under fully controlled conditions.

Where is AIB commonly found?

Asbestos insulation boards were widely used across both residential and commercial buildings. Because of its versatility, it was applied in many structural and decorative areas, especially where fire resistance was needed.

Typical residential and commercial applications

- Garage ceilings

- Boiler cupboards and electrical panels

- Riser panels for internal pipework

- Soffits and external overhangs

- Partition walls and suspended ceilings

- Firebreaks and duct linings

If your property was built before 2000, especially before 1985, it may well contain AIB. Even modernised homes may still hide it in unrenovated areas. Visual inspection alone is not enough — AIB can look nearly identical to plasterboard or MDF. That’s why we always recommend testing before touching.

Why professional asbestos board removal is essential

AIB removal is not DIY territory. It is a licensed and notifiable process, meaning it must be:

- Done by a contractor with an active HSE license

- Notified to the HSE at least 14 days before work begins

- Executed using specialist enclosures, air control systems, and decontamination units

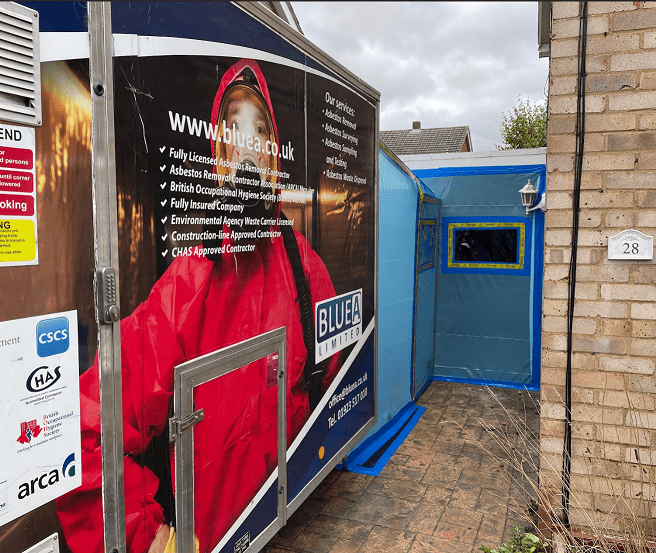

At Blue A Ltd, we hold the maximum 3-year HSE license and undergo regular unannounced inspections from HSE officers. This ensures every project meets the highest standards for safety and legal compliance.

The danger with AIB isn’t just what you can see — it’s what you can’t. Once fibres go airborne, they’re invisible, inhalable, and deadly. That’s why our team uses negative pressure units, full RPE, and sealed enclosures to stop fibres from escaping.

Our goal is simple: maximum safety, zero shortcuts.

Identifying asbestos in insulation boards

How do I know if my insulation board contains asbestos?

The easiest indicator is the age of your property. Asbestos insulation board was a common building material until 1985, and wasn’t fully banned in the UK until 1987. Unfortunately old stock was still circulating across suppliers for a few years after the ban. Asbestos was first banned in 1985, when products containing high percentages of asbestos were withdrawn from the market. Then, in 1999, the ban was extended to virtually all asbestos products.

Here’s a general guide:

- Before 1985 – Highly likely to contain asbestos

- 1985–1990 – Likely to contain asbestos

- After 1990 – Unlikely to contain asbestos

But be cautious — renovations, repairs, or partial replacements may have altered what’s visible. A ceiling from the 1970s might look modern but still contain hidden AIB. Because of that, we always assume asbestos is present until proven otherwise.

The only accurate way to identify asbestos is through lab testing. If you don’t already have an asbestos survey or test certificate, we can help you get one — fast and hassle-free.

Why can’t I identify asbestos visually?

You can’t. The asbestos insulation board looks almost identical to modern insulation boardor MDF. There are no consistent visual cues — not even for professionals. That’s why trained surveyors collect samples using safe, controlled methods and send them to accredited labs for analysis.

At Blue A Ltd, we always insist on confirmed lab results before proceeding with asbestos board removal, because guessing isn’t just risky — it’s illegal.

Our asbestos board removal process

What happens before we start?

Every asbestos board removal project begins with meticulous preparation. Because AIB is highly friable, we create a detailed work plan, typically spanning 20–30 pages, even for one-day jobs. This documentation is legally required and submitted to the Health and Safety Executive (HSE) at least 14 days before work begins.

Our projects are regularly inspected by HSE officers — often without notice — so we maintain the highest operational standards at all times.

How do we set up the removal area?

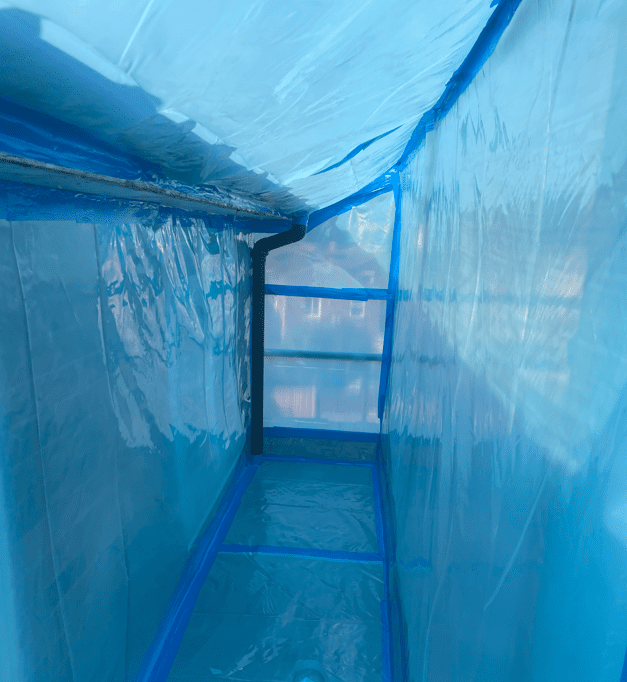

We build a bespoke airtight enclosure around the area where the asbestos boards are located. This prevents fibre release into the rest of the property.

The enclosure is constructed using:

- 2x2 timber

- 1000-gauge polythene

- Corex boards

- Cloth tape

- Spray tack

We cover all porous and hard-to-clean surfaces, including carpets, radiators, home appliances, vents, and windows. The result is a fully sealed, secure workspace.

What is an airlock and why is it important?

Each enclosure is fitted with airlocks, which:

- Control airflow, ensuring fibres stay inside enclosure

- Help create negative pressure, pushing contaminated air toward filtration units

- Allow operatives to enter and exit safely

How does the negative pressure unit work?

Our enclosures are fitted with industrial-grade negative pressure units. These ventilators suck air from inside the enclosure, forcing it through HEPA filters before venting it outside. This creates a controlled environment with dust-free air within seconds, minimising risk for everyone on-site.

What is the decontamination unit used for?

Every licensed project requires a 3-stage decontamination unit — a mobile shower and changing area for the crew. Here’s how it works:

- Before entry, the team changes into double disposable overalls, washable transit shoes, and puts on a full-face respirator.

- After removal work, they dispose of their suits and shower thoroughly before changing back into clean clothing.

- This process ensures that no asbestos fibres leave the enclosure.

How are the boards removed safely?

The method depends on how the boards were fixed:

- Screwed panels: unscrewed manually while shadow vacuuming with an H-type (HEPA) vacuum

- Nailed or glued panels: soaked with wet strip solution to reduce fibre release, then gently prised away and removed whole where possible

We never use power tools. Everything is done by hand to reduce dust and maintain full control.

Cleaning and decontamination

Once the asbestos insulation boards have been removed, the real work begins — thorough cleaning of every exposed surface inside the enclosure. Our goal is simple: leave the area cleaner than we found it, with zero asbestos fibres remaining.

Here’s how we do it:

- All timber surfaces are scrubbed using handheld abrasive tools to remove any embedded debris or scarring.

- Screw or nail holes are drilled out with oversized drill bits to eliminate any hidden fibres.

- Metal surfaces are cleaned using H-type vacuums and disposable rags, since they’re non-porous.

- All high-level edges are vacuumed.

- The entire enclosure, including polythene sheets, is vacuumed and wiped top-to-bottom using wet rags and HEPA-filter vacuums.

- Once everything is cleaned, the polythene sheeting is carefully removed and bagged as asbestos waste.

- The floor gets one final vacuum pass, and the negative pressure units continue running throughout the entire process to keep the air fibre-free.

This isn’t just about asbestos. We also eliminate other contaminants like carpet fibres, fibreglass, and general construction dust — leaving you with a truly clean, re-occupiable space.

Waste disposal and documentation

Every piece of asbestos waste is double-bagged — first in a red bag, then a clear one — and sealed with 3-inch cloth tape. These are standard, UN-approved asbestos waste bags.

Waste is taken to a registered asbestos landfill, and you’ll receive an official Waste Consignment Note, which:

- Proves the asbestos was disposed of legally

- Is required for your own legal compliance

- Contains a unique reference number you can use to track the disposal

Disposal costs make up a large part of any asbestos removal quote. With landfill prices on the rise, illegal fly-tipping is more common — but not with us. Blue A Ltd is a licensed waste carrier, and we never leave waste behind, unlogged, or unaccounted for.

Air testing and clearance certification

Because AIB is a high-risk material, the job isn’t complete until an independent analyst signs off the area using a 4-stage certificate of reoccupation. This is how we ensure the environment is safe to re-enter:

- Stage 1: The analyst checks that our work plan is site-specific and that HSE notification was properly filed.

- Stage 2: A full visual inspection of the enclosure is carried out.

- Stage 3: An air test inside the enclosure measures fibre levels post-removal.

- Stage 4: Once cleared, the enclosure is dismantled. A final inspection is done before the area is officially deemed safe for reoccupation.

If needed, we can also arrange air monitoring in adjacent rooms or throughout the property during removal. This allows us to verify that our working methods are effective — and your environment remains uncontaminated.

Reinstatement after asbestos board removal

Once the asbestos boards have been removed and the area is certified clean, we can help put everything back together. At Blue A Ltd, we offer in-house reinstatement services and work closely with trusted subcontractors where needed.

Depending on your project, reinstatement may include:

- Installing new plasterboard ceilings or walls

- Skimming and finishing surfaces

- First-phase decoration (paint prep, mist coats)

- Reinstating electrical fixtures

- Light carpentry or structural works

You don’t need to hire a second contractor. We handle the full process — from safe removal to restoration — keeping your project moving efficiently and legally.

Getting a quote for asbestos board removal

Every asbestos board removal job is unique. Because of the need for custom-built enclosures, we usually need to visit your property to provide an accurate, free of charge, fixed-price quote.

However, if you can’t book a site visit right away, we may be able to offer a desktop estimate. For that, we’ll need:

- A positive asbestos survey or lab result confirming AIB

- A floor plan of the area (if inside)

- Photos and measurements of the space and surrounding rooms

- Info about parking access, power supply, and water availability

- Optionally, we can set up a Zoom or video call

This lets us assess your space remotely and prepare a ballpark quote — fast and free.

Why choose Blue A Ltd

We’re not just licensed — we’re experienced, proven, and trusted.

With over a decade of experience and more than 11,000 successful removals, Blue A Ltd is one of the UK’s most reliable names in asbestos board removal. We are:

- Fully HSE-licensed (3-year license)

- Regularly audited and inspected by the Health and Safety Executive

- Committed to full legal compliance and documentation

- Known for zero-compromise safety standards

- Available for projects across London, Hertfordshire, Bedfordshire, Buckinghamshire, Essex, Surrey, and beyond

We treat every job like it’s our own home — because safety isn’t optional.

BLUE A LTD

VAT No: GB 153 4880 02

Company No:08355657

HEAD OFFICE

1 Handford Court

Garston Lane, Watford

WD25 9EJ

CONTACT US

phone: 01923 609858

e-mail: office@bluea.co.uk